In recognition of the importance of training in all matters where safety is concerned, a new Hazmat course has been added to the training schedule.

When asked about employee training in general, Steve explained that although AMS has a great safety record, there is a lot of space to keep safe, equipment to become aware of, conveyor belt systems, pallets and forklifts, sharp edges, various carts in movement, and numerous places where carelessness or inattention could lead to a serious safety concern. The additional concern that is now being addressed is recognition of hazardous materials and procedures to use when handling and shipping such materials.

AMS does not commonly store and ship hazardous materials, and yet, in an effort to assure the full safety of employees and the public, management determined that employees should be trained on how to meet the standards of certification for materials that might be considered hazardous, and how to recognize such materials.

The standards for Hazmat training in the US have been established by the Department of Transportation (DOT), and AMS uses these standards in their training program.

Some of the information that employees receive in training can include how to identify hazardous material and define it, reporting requirements, how to determine the hazard class and select packaging and labeling, how to segregate, load, block and brace hazardous material and so on. Transportation of a hazardous material in commerce includes movement, loading, unloading and storage during transport, so training must teach how to transport by air, rail, vessel and motor vehicle.

Also included in training is emergency response information, self-protection measures and accident prevention methods and procedures. The goal is awareness and familiarization training designed to provide familiarity with DOT regulations for shippers, transporters and manufacturers. In essence, although contact with hazardous materials is unlikely, for the protection, safety and security of AMS employees and the public, this function-specific training for the AMS warehouse employees is taking place.

Steve Perez spoke about the likelihood of AMS employees encountering hazardous materials, and the reason for Hazmat training, saying, “At AMS we do handle materials that require certification. Even though these materials might not be considered truly hazardous, their handling and shipping requires training.”

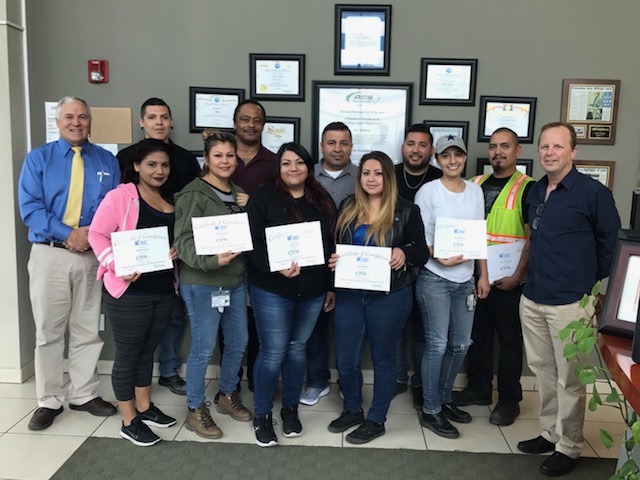

The safety and security record at AMS is top notch, and intentionally so, for the protection of both employees and clients. Congratulations to the employees for their successful achievement of Hazmat training.